Consulting Frameworks Series: Improvement and Problem Solving Frameworks (Part 4)

In the previous publications of this consulting framework series, we have looked at the frameworks used to set the foundations for any company. It is now time to shift our focus to the next part – Improvement and Problem Solving frameworks in consulting. So, what are improvement and problem solving frameworks all about, and which are the more renowned ones? For that, you’ll have to continue reading to find out!

Improvement and Problem Solving Frameworks

Improvement relates to implementing methods to improve or even continuously improve business processes. On the other hand, problem solving is regarded as a plain and simple process that helps with finding a solution to any kind of problem. This means improving your solutions in order to solve the issues at hand.

There are several steps that are taken into consideration; right from identifying and determining the cause of the problem, right up to seeking a viable and effective solution. Hence, if put together they form improvement and problem solving frameworks, which are essential for any business to run efficiently.

The Main Improvement and Problem Solving Frameworks in Consulting

As most of you know, there are plenty of frameworks going around and the same can be said about improvement and problem solving frameworks as well. Hence, let us look closely at a few of the top-notch improvement and problem solving frameworks that are available to us.

#1. The Reframing Matrix

The Reframing Matrix is a well-renowned and widely used tool that was created by Michael Morgan. It is a problem solving framework that he has gone on to publish in his book titled “Creating Workforce Innovation”.

This particular matrix is all about looking at problems (especially business problems) from various perspectives. By doing so, it helps with coming up with different and creative answers or rather solutions to the business problem.

The method is based on the assumption that various people with varied experiences will approach challenges in different ways.

The strategy allows you to put yourself in the thoughts of different people, picture how they might approach these difficulties, and investigate the potential answers that they might propose. Furthermore, this tool is extremely easy to use and requires only three steps to follow.

Step 1: Draw The Grid

The first step is all about getting the grid drawn. Its simply drawing four squares together with leaving some space in the middle of the four squares to write down the actual problem.

Step 2: Decide On Perspectives

Now it is time to decide on the four different perspectives that should be included in the matrix. For this, there are two approaches that can be followed; i) the 4P’s approach, and ii) the professions approach.

In the case of the 4P’s approach, it is all about the different approaches that needs to be adhered to. So, basically, the 4P’s are – product perspective, planning perspective, potential perspective, and people perspective.

Go through each perspective carefully and ask necessary questions in order to find a proper solution. For instance, in product perspective, questions such as “Is there anything wrong or faulty with the product or service? Is the product priced correctly? Can this product or service be trusted?”

Once the questions are laid out for each perspective, it becomes relatively easier to move ahead in this process.

Step 3: Brainstorm Factors

Lastly, it is time to create a list of factors that relate to the problem from each perspective. And once the matrix is complete, a clear picture will be formed that will help with properly understanding the issue and help with finding good and effective solutions.

#2. The Five Why’s Analysis

The five why’s analysis was created by Sakichi Toyoda, a Japanese industrialist, inventor, and founder of Toyota Industries. This technique was developed way back in the 1930s and became popular in the 1970s. It was one of the more renowned improvement and problem solving frameworks in the world. And today, a huge chunk of businesses still makes use of this effective method.

It’s an extremely simple technique because when a problem arises, it is essential to jot down the root cause of the problem by simply asking “Why” – not once, but as many as five times. Then, when a counter-measure becomes evident, you implement it to avoid a recurrence of the problem.

Furthermore, when conducted in a team setting, the Five Why’s analysis is significantly enhanced and there are five essential points to keep in mind.

- Write Down The Problem: Make a note of the exact issue or problem that arises. Writing the issue down enables you to formalize and fully articulate the issue. Additionally, it assists the team or group in focusing on the same problem.

- Ask The First Why: Here, it becomes necessary to inquire “Why” the problem occurs. And then jot down the answer below the problem.

- Follow Up With The Second Why: If the answer you just offered does not address the fundamental cause of the problem you noted at the start, then repeat the question “Why” again and note down the response.

- Ask More Whys: Until and unless the whole group or team does not agree that the root cause of the problem has been discovered, you should keep asking more ‘Whys’.

- Eliminate The Problem: After the root cause of the issue has been finally determined. And verification and reasoning behind the analysis has been made, it’s time to develop corrective steps to eliminate the root cause from the system.

#3. Fishbone Diagram by Kaoru Ishikawa

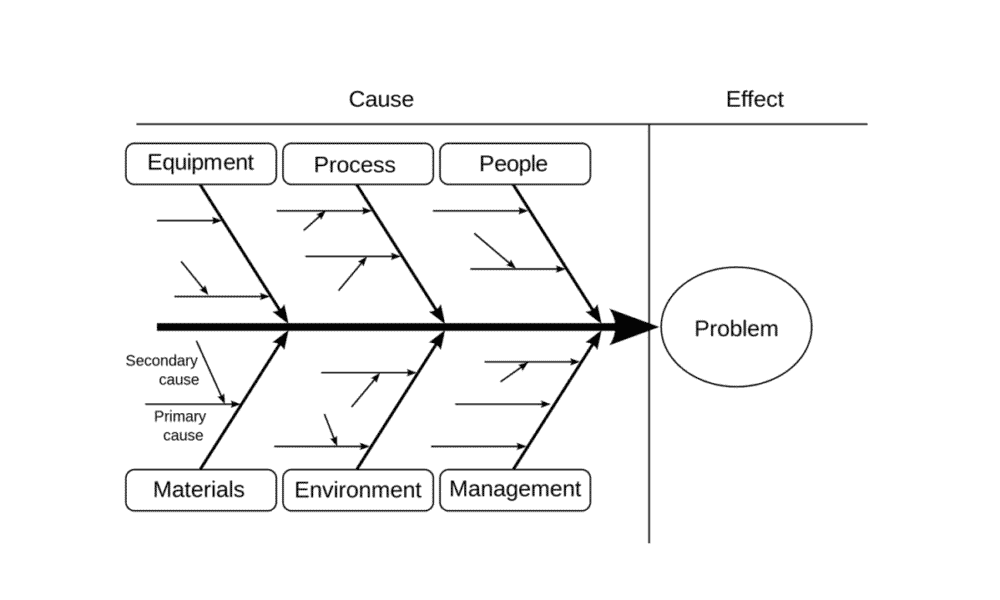

The fishbone diagram by Kaoru Ishikawa, which is also known as the Ishikawa diagram or Cause-and-effect diagram, was developed way back in the 1960s. It is an extremely useful tool that supports and helps organizations in categorizing potential causes of problems or issues through a systematic approach that assists in identifying the root cause(s) of an effect, problem, or issue. Moreover, it is one of the more widely used improvement and problem solving frameworks in the world.

Ishikawa’s fishbone diagram is built on three main components. They are:

- The main activities and inputs that go into making the final product.

- The issues that were observed within the above-mentioned activities and inputs.

- The problem that needs to be fixed.

Moving on, to create this Ishikawa diagram, there are certain steps that need to be followed. They have been listed down below.

Step 1: Draw the main layout, i.e., a fishbone head and spine.

Step 2: List down the problem/effect that needs to be studied in the fish’s head.

Step 3: Now add the bones at the spine and label the categories.

The categories can be categorized as follows:

- The 4 P’s (People, Place, Procedure, and Policies)

- The 4 S’s (Surroundings, Suppliers, Systems, Skills)

- The 6 M’s (Methods, Machines, Materials, Manpower, Measurement,

- Management)

Step 4: Now, label the causes and reasons under the specific categories.

Furthermore, an Ishikawa diagram would typically look like this.

#4. CIRCLES Method

The CIRCLES methodology is a wonderful and highly efficient approach that enables product managers to deliver relevant responses to inquiries from design, marketing, customer success, and other teams or departments. It is also regarded as one of the best improvement and problem solving frameworks going around.

This particular framework was created by Lewis C. Lin, author of the book titled “Decode and Conquer”. In his book, he talks about the CIRCLES method and much more. Moving on, the CIRCLES method involves seven simple steps:

- Comprehend The Situation: The first step is all about comprehending the situation at hand and asking yourself the 5W’s + H (Who, What, Why, When, Where, and How).

- Identify The Customer: The next step involves knowing your target audience by identifying them in order to build your product or service.

- Report Customer’s Needs: Once the target customers have been identified, it is time to rely on your customer research report in order to uncover the pain points and adhere to their respective needs.

- Cut Through Prioritization: This step involves omitting all unnecessary ideas, tasks, and solutions, and prioritizing them in order to achieve the desired goals.

- List Solutions: This is an extension to the above step wherein proper solutions should be jotted down in order to tackle the problem at hand. It is imperative to have a clear-cut plan of action for the solution to be carried out.

- Evaluate Trade-offs: When designing a product, product managers must consider three primary factors: simplicity of use, customer satisfaction, and revenue. By balancing these three factors, the product team may fulfill its goals while balancing restrictions and limitations.

- Summarize Your Recommendations: This final step summarizes all of the product design elements and attributes covered in the previous six steps of the CIRCLES approach.

#5. Trial And Error Method

Edward Lee Thorndike, a renowned educational psychologist, came up with this theory called the “the trial and error” method. As per the great man, learning takes place by trial and error. By this, he meant that when there is no ready-made solution available to a particular problem, then one must adopt the trial and error method.

Basically, this method is all about trying one solution and seeing if it helps. If it does not, then reject it, and move to another solution. Doing so, you eliminate errors or irrelevant responses which do not serve the purpose and you can finally discover the right solution to your problem.

Moreover, one thing to keep in mind here is that there are often systematic and relevant reactions even in trial and error. The activities aren’t entirely random. All of these seemingly random behaviors are given by the situation, and the learner proceeds appropriately.

#6. Six Sigma Model

Six Sigma is a measurement-based process improvement framework and one of the top improvement and problem solving frameworks, currently. It is a system aimed at streamlining processes and boosting customer satisfaction (both internally and externally).

This method is based on the idea of reducing process variance. Processes produce consistent and desired results as a result of this reduction. As a result, the goal of this strategy is continuous process improvement with few faults. The Six Sigma framework can be executed through methodologies and the two main ones are: DMAIC and DMADV.

I) DMAIC: This particular methodology is an acronym that focuses on incrementally improving and enhancing existing processes. It is regarded as one of the well-known methodologies that are associated with Six Sigma. Hence, let’s break down the acronym and decipher its overall meaning.

D Stands for Define – It is all about defining the needs of the customers, its necessary requirements, and project goals.

M Stands for Measure – Here it is all about measuring the key and critical aspects of the current process. So basically, this is the step where you begin to comprehend the process and collect important data.

A Stands for Analyze Data – Analyzing data in order to uncover the root causes of a problem.

I Stands for Improve – Locating means and ways to improve the process.

C Stands for Control – To effectively control the process and see how it can be done in the near future.

II) DMADV: The DMADV methodology can be used to create new processes as well as new products and services. Its acronym is given below.

D Stands for Define – Here it is all about clearly defining and setting the project goals.

M Stands for Measure – This step involves properly measuring the important components of the process, and at the same time, the capabilities of the product or service.

A Stands for Analyze Data – It involves analyzing the data and developing numerous designs and then picking the best one for use.

D Stands for Design – At this step, it is purely all about the design and test details of the process.

V Stands for Verify – The need to validate the design using simulations and a pilot program before passing the process over to the client.

#7. Benchmarking

Benchmarking is a framework that allows firms to compare their metrics to those of their competitors. Often, this entails analyzing factors connected to a company’s operations and performance. Benchmarking metrics that are commonly used include:

- Production Costs: Production costs are the expenses incurred by a firm when it manufactures a product or provides a service. Expenses such as raw materials and labor can be included in this category.

- Employee Turnover: Employee turnover refers to the rate at which a business loses employees over a specified period of time owing to specific circumstances such as termination and retirement.

- Revenues: Revenues are the overall amount of money earned by a corporation from the sale of a product or service.

- Process Cycle Time: Process cycle time is the amount of time spent by a team creating an item for an organization.

- Cost ratios: Innovation cost vs revenues, SG&A vs Headcount, …. those allow to keep costs in check vs competition

#8. Plan-Do-Check-Act (PDSA) Cycle

Dr William Edwards Deming, a management consultant in the 1950s, devised a system for determining why some goods or processes do not perform as expected. His technique has subsequently become a widely utilized strategy tool for various types of businesses.

It enables them to develop hypotheses about what should change and then test those hypotheses in a “constant feedback loop.” Thus came the invention of the PDCA Cycle, which is also known as the PDSA Cycle. Moreover, this cycle is considered as one of the top improvement and problem solving frameworks globally.

The PDCA Cycle, which means Plan-Do-Check-Act can also be called PDSA, which elaborates to Plan-Do-Study-Act. This cycle allows you to address problems and execute solutions in a systematic and logical manner and is used by many all around the globe.

Let’s take a closer look at each of the four stages one by one:

Stage 1: Plan

The first stage is to define your issue or opportunity. Maybe your finished product isn’t up to par, or your marketing strategy may need some improvements. Thus, its important to examine all the data that is accessible and then create, screen, and implement concepts that will help. Hence, the plan is the first and foremost step, and perhaps even the most important.

Stage 2: Do

Once you’ve figured out a proper solution, try it out in a small-scale pilot project. This will help in revealing whether or not your planned adjustments are working with minimal impact on your operation. For instance, you could conduct a small trial inside a particular department.

Stage 3: Check or Study

The next stage involves checking or thoroughly studying the results of the pilot project. It is important to analyze and assess the results and see whether or not it was a success. If it was, then move to the next stage. If not, then go back to the first stage and start again.

Stage 4: Act

In the final stage, you’ll actually put your plan into action. But keep in mind that the PDCA/PDSA cycle is a loop and not a process. Your improved process or product becomes the new standard, but you are always looking for methods to improve it more.

A Quick Round-Up

Improvement and problem solving frameworks are crucial to any organization, big or small. It is extremely essential for businesses to implement and be able to improve their processes and solve their main problems in order to function well and achieve their desired goals with ease.

Hence, the above-mentioned improvement and problem solving frameworks are proven to work effectively and efficiently and businesses should opt for them. Are you implementing any of these improvement and problem solving frameworks in your organization? Let us know!

Author

Laurent Thomas

Capabilities

Operations, Risk & Compliance, Business Transformation

Industry

Agriculture, Professional Services

Language

English

Location

Asia, Europe, Latam, Africa, North America, Oceania, Middle East

Type

Official

0 Comment